How to use epoxy resin?

Are you looking for the right way to use epoxy resin? Find below all the answers to your questions.

This article was developed by the Sicomin technical team, a leader in the formulation and manufacture of epoxy systems, with 30 years of experience in developing high performance epoxy systems.

What is epoxy resin?

Beyond technical definitions, epoxy resin is a liquid thermosetting polymer often presented in two components. When exposed to heat (minimum temperatures of 10 to 15°C), it begins to polymerize, gels and becomes solid. Here are some basic points for those using this product for the first time.

Epoxy resins or "epoxies" are solid or liquid linear polymers mainly obtained by the reaction of epichlorohydrin and a polyphenol.

The most commonly used reaction is the one involving the epoxy function with diamines (hardener). This reaction occurs at room temperature. The result is a three-dimensional polymer, also called thermosetting, rigid, with high mechanical properties.

Advantages of epoxy resin

Epoxy systems have many advantages:

- Good hydrocarbon resistance

- Good chemical resistance

- Good mechanical properties

- Adhesion to almost any substrate

- Very low shrinkage which allows for low internal stresses

- Price/Performance

Disadvantages

- Low UV resistance

How much epoxy resin/hardener mixture should be prepared?

We advise you to start with small quantities, about 100g of mixture so that you can test and adapt to the reactivity of your mixture.

Then if necessary increase this quantity.

How to choose the right reactivity of the hardener?

It is important not to choose a hardener that is too fast. Indeed, if it is not applied in the allotted time, it will harden in the mixing pot and generate a high exothermic temperature.

Therefore, for fast systems, it is better to prepare several mixes as the work progresses.

On the other hand, the use of a slow hardener will increase the setting time of your project. It is therefore better to choose a slightly faster hardener. This is often the case in winter when low temperatures tend to slow down the systems.

The working time (potlife) should be longer than the estimated application time.

How to prepare and dose the epoxy resin?

Caution! Unlike polyester, to succeed in mixing epoxy resin, it is important that the dosage is precise.

The dosage of a mixture can be done in two different ways: by weight or by volume.

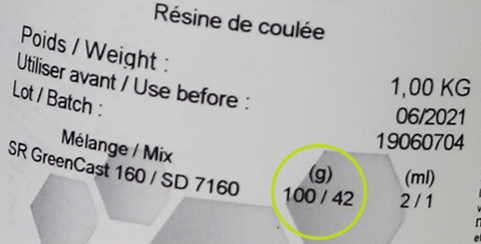

Ponderal

To make a weight mixture you will need an electronic balance whose accuracy is adapted to the mass to be weighed. First, place the empty beaker on the electronic balance and tare the beaker. Then, pour the quantity of resin into the graduated beaker. In this example we will take 100g for the amount of resin we have weighed.

Use the mixing ratio that you will find on the label of the cans or on the product data sheet. In this example the mixing ratio is 100/42.

Example of calculation:

Given that the amount of resin is 100g we need to perform the following calculation to determine the amount of hardener to add to the mix.

Calculation: 100 (quantity of resin) x 1.42 (ratio of dosage 1 + (42/100) = 142 (total quantity). According to the calculation, the total amount of the mixture will be 142g.

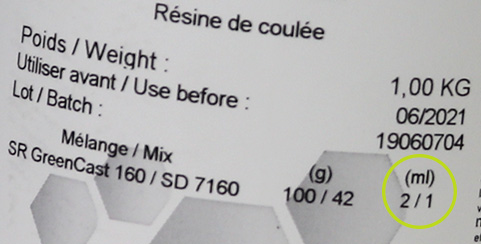

Volumetric

For volume mixing, you will only need a measuring cup. First, pour the amount of resin into the beaker. Here we will take 100ml as an example.

Use the mixing ratio that you can find on the label of the cans or on the product data sheet. In this example the volume ratio is 2/1.

Example of calculation:

Given that the quantity of resin is 100ml we will have to make the following calculation to determine the quantity of hardener to add to the mixture.

Calculation for 2/1 volume: Resin 2x50ml = 100ml / Hardener 1x50ml = 50ml. According to the calculation, the quantity of hardener to be added is 50ml.

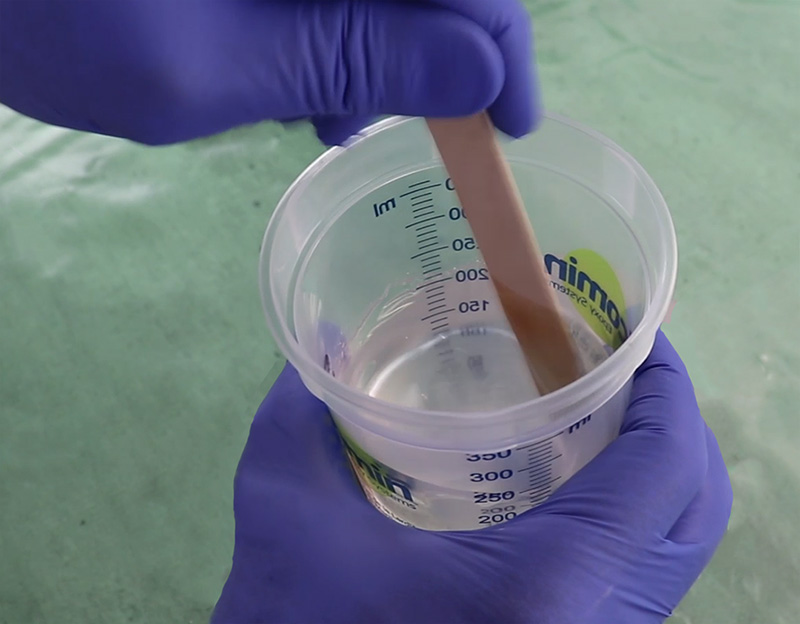

How to mix epoxy resin and hardener?

Mix the resin for about 2-3 minutes. Your mixing should be done slowly, scraping the edges and bottom of the cup. It is recommended to mix in a figure of 8. This step is important. If it is not done correctly :

- The mixture will not be homogeneous

- Risk of optical defects

- Risk of surface defects (sticky, waves...)

Be careful, if your resin and hardener have a very large difference in viscosity you must mix very slowly to limit the risk of splashing.

Beware of the "Mass" effect of the resin

Epoxy resins are thermosetting resins, which means that they release energy in the form of heat during their polymerization, and heat increases their polymerization speed. Therefore, the more the casting is important, the more the reaction produces heat, it is the mass effect.

How long does it take to demould and machine the part made of resin?

The rate of chemical reaction is influenced by the temperature of the room you are working in. A low temperature will slow down the chemical reaction and may prevent your resin from curing, while a high temperature may speed up the reaction.

How to accelerate the hardening of the resin-hardener mixture?

The rate of the chemical reaction is related to several factors:

- Temperature:

- The higher the temperature, the faster the resin will harden. Be careful not to heat too much, the resin could yellow or crack.

- The lower the temperature, the longer the demolding time. If the temperature is too low, the reaction may stop.

- Mass:

- The more the mass is important the more the resin will have difficulty to evacuate the calories generated by the reaction. As a result, the internal temperature of the resin will increase and auto-accelerate the reaction.

- Mold:

- If the mold is insulating the reaction will be faster than in a conductive mold. As for the mass effect, the calories that are not evacuated (in the insulating mold) will tend to accelerate the reaction.

Be careful, the temperature should not go below 15°C as this may create an incomplete reaction.

Precautions to take with epoxy resin!

Epoxy resin can be dangerous if not handled with care. To avoid this, we advise you to use personal protective equipment (PPE) according to the handling you are doing, such as nitrile gloves, protective clothing, a suitable respirator or safety glasses.

English

English Français

Français