Epoxy Resin SR 8450 + Slow Hardener SD 8451

Pot-Life for 500 g of mix at 20°C : 9 h

Pot-Life for 500 g of mix at 20°C : 9 h

Pot-Life for 100 g of mix at 20°C : 2 h 15 min

Pot-Life for 500 g of mix at 20°C : 2 h 40 min

Pot-Life for 100 g of mix at 20°C : 38 min

Pot-Life for 500 g of mix at 20°C : 70 min

Pot-Life for 100 g of mix at 20°C : 37 min

Impregnation diluent 1 litre

Pot-Life for 100 g of mix at 20°C : 35 min

Pot-Life for 100 g of mix at 20°C : 20 min

Laminating:

SICOMIN wood epoxy system are use to laminating e-glass fiber on wood surfaces.

Used on Hand lay up, Peeltex allow to obtaining a very good quality surface and laminating at 80% the sanding step before coating, bonding or second laminating step.

Coating or epoxy varnish:

Specifically developped for boat industry, SICOMIN epoxy varnishes can use with all wood surfaces, every pieces of boat and all sizes at room temperature. They cure at room temperature, and after application,

the surface is bright and can be sanded even then.

Bonding and fillet joints:

This is the most common method of assembly in modern shipbuilding. A fillet joint is constituted by a loaded system applied in the angle formed by two panels to be assembled. This method is ideal when assembling parts that meet at different angles: partition at the shell, inner shell connecting bridge, chairs, chests ...

Glulam beams:

The technical advantages are obvious:

- Improved mechanical properties: the adhesive joint is mechanically stronger than the lignified cells of the wood. Bond two pieces of wood, that is interposing a polymer adhering perfectly to the support, reconstituting between these two parts of the upper mechanical connections to the single piece of wood. The bonding is welding, the metallurgical sense.

- The probability of rupture due to wood defects (knots) are reduced by their dispersions and by correction of adjacent lamellae.

- The composite laminated enables designs optimized for example with blades of more resistant wood of area, low density wood in the center, multidirectional reinforcements ... everything is possible.

- easy and accurate realization of complex shapes: Glulam enables plastic virtuosity.

- The strips are cut or sliced into often cheaper wood pieces, smaller or falls.

- Production of large lengths with relatively short strips.

- Parts Realization curves small radii by sipes of small thicknesses.

- Reliability over time: moisture resistance and bacteria improved by the glue joint, aging without alteration of technical performance.

- Aesthetic: Wedding of species and colors.

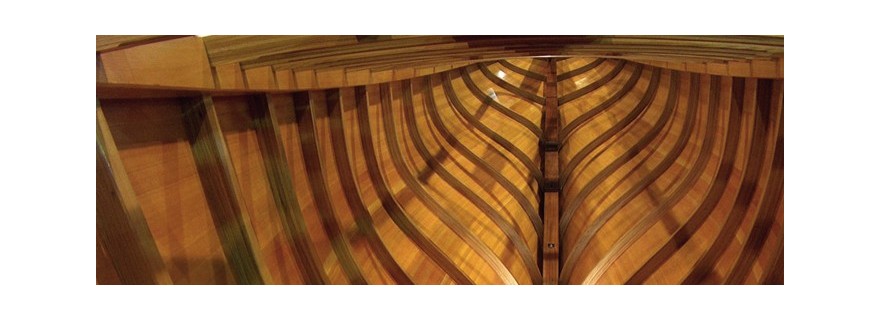

Strip planking :

The Strip planking is the fastest and easiest method of sandwich constructions. Relatively thick smooth a low density wood constitute the core of the sandwich. Asked outside couples to form a male model (sometimes female), they will then be laminated on both sides.

Applications of wood epoxy system:

- Boat industry

- interior design, decoration

- Others sectors: boating, leisure, industry, etc ...